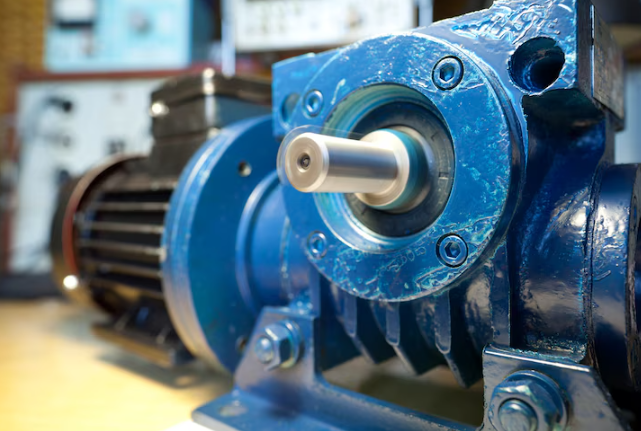

Rotary screw compressors are an important part of any Industrial rotary operation. It offers reliability and optimum efficiency. It comes in handy when compressed air is the most productivity enhancing tool needed in a high pressure environment.

Their Operation

The parts of the rotary compressors work together to squeeze or compress air from two interlocked components within a defined region. The male rotor having a dual capability performs better. It delivers a smooth outcome air with ease.

Compression Steps Air Filling:

The output of rotary air compressors leads to better consistency as compared to piston compressors.

Most industrial rotary screw compressors use oil injection for lubrication, seal, and coolant functions, which is then separated from the compressed air before delivery. Oil-free models utilize specialized surface coatings along with external cooling systems to avoid oil contamination and achieve similar results.

Advantages Over Other Types

Low Noise: Unlike reciprocating models, screw compressors operate at significantly lower noise levels ranging between 65-75 decibels, making the unit suitable for installation in occupied spaces or noise-sensitive areas.

High Efficiency: inversión en Rocio’s turn down feature along with compression ratio provides a more efficient energy utilization surpassing reciprocating compressors by 10-15%. This enhanced productivity translates to substantial savings on operational costs.

Longer Lifespan: Quality rotary screw compressors with lower moving parts designed for continuous operation can reliably run with proper maintenance for 15-20 years. In comparison, reciprocating units last 8-12 years.

Fewer Maintenance Requirements: Relatively, these units experience less disruption compared to rotary compressors. Scheduled maintenance intervals are 2,000-8,000 hours while for rotary compressors it is 500-1,000 hours.

Superior Air Quality: Advanced filtration systems and separation technologies yield the air under preset conditions, with higher accuracy and reliability than conventional systems, making it vital for sensitive applications, pneumatic tools, and machines needing cleaner and drier air.

Performance Characteristics

Duty Cycle Capability: Unlike other types of air compressors, Rotary screw compressors have a distinct edge since they can function without any downtimes for cooling. This makes them suitable for situations where a constant supply of air is demanded.

Pressure Stability: The commanding pressure of most advanced control systems is maintained within a window of ±2 PS, which is very convenient for the optimal functioning of secondary pneumatic tools and processes working after the compressor.

Energy Management: Many modern units employ advanced air consumption monitoring features which restrict energy use during air consumption when it is lower than the preset threshold, making sure there is no energy wasted during low consumption periods.

Applications

Manufacturing Plants: Aiding in pneumatic assembly lines, robotic systems and automated machines which require large amounts of air on a steady basis with minimal fluctuations in pressure.

Automotive Shops: Supporting paint booths, tire inflators, pneumatic lifts and air tools makes a shop more efficient. Providing reliability and consistent pressure ensures customer satisfaction.

Food and Beverage Processing: Supplying clean oil free air complies with stringent hygiene and safety standards while powering packing machines, conveying systems and other automation processes.

Medical and Pharmaceutical Facilities: Reliable oil free air aids critical elements in life support systems, laboratory equipment and manufacturing processes where the air for instruments must be flawless.

Construction and Contracting: Provides power for numerous pneumatic hand tools during job sites to allow simultaneous tool usage. Rugged dependability during continued use on different sites ensures constant productivity and the ability to keep to timelines.

Selecting The Right Model

Capacity Requirements: Compile a list of all pneumatic equipment that might operate concurrently to compute your total CFM (Cubic Feet per Minute) requirements. Then add a 20-30% compressor buffer for peak demand periods.

Pressure Specifications: Think of the highest-range applications for your equipment. What is the maximum pressure (PSI) you can afford to lose in the filters and throughout the distribution system?

Choices for Power Sources: Based on your site layout, select between electric (single or three-phase) and diesel power. Electric is more advantageous for indoor locations while diesel is better for remote or portable settings.

Tank Size Considerations: Smaller receiver tanks are portable and have a lower initial investment, while larger ones improve pressure stability and improve rpm cycling of the motor.

Built-in Features: Think about offered pre-installed air dryers and filtration systems as well as variable speed drives that improves the quality of air by lowering energy consumption and providing simplified installation.

Control Systems: More recent units come with high tech controllers that allow remote monitoring, maintenance scheduling, and energy savings that are beneficial to long-term operational costs.

Installation and Setup Considerations

For proper installation and cooling/fans, there must be ambient temperature condition exhaust that matches the equipment’s specifications as well as peripheral electric setup for the unit’s requirements. Ensure air compressed systems align with the application needs. Extreme hot or cold temperatures can impact efficiency, so consider those as well.

Recommended Practices In Equipment Maintenance

Create a routine comprehensive inspection and servicing schedule like: oil, filter change, separators replacements, and system checks. Comprehensive maintenance or servicing kits with checklists are provided by the manufacturers alongside detailed servicing timelines to ensure equipment durability and warranty maintenance.

Summary

Having a rotary screw air compressors provides industry unmatched reliability and efficiency. In any industry where compressed air is used, upgrading from outdated machinery or starting anew with rotary screw compressors improves productivity, lowers servicing maintenance, and saves energy costs providing a long term investment. The continuous operation capability coupled with high efficiency and top of the line control features makes these rotary compressors the unrivaled choice for industrial application and operations where uptime and dependability is critical.